从建井到弃井的整个过程中,确保油井的完整性对于避免对人、环境和资产造成损害至关重要。

来自 | BHGE

编译 | 白小明 影子

井筒完整性失效造成的灾难性事故,正成为行业对相关保障措施的实施和评价进行改进的主要驱动因素。对保障措施的评估必须在任何可能的条件下均得力、可靠、及时,只有这样,它才能在对当前的油井作业采取降低风险的决策中发挥重要作用,才能在后续井作业中改善保障措施的实施和性能。

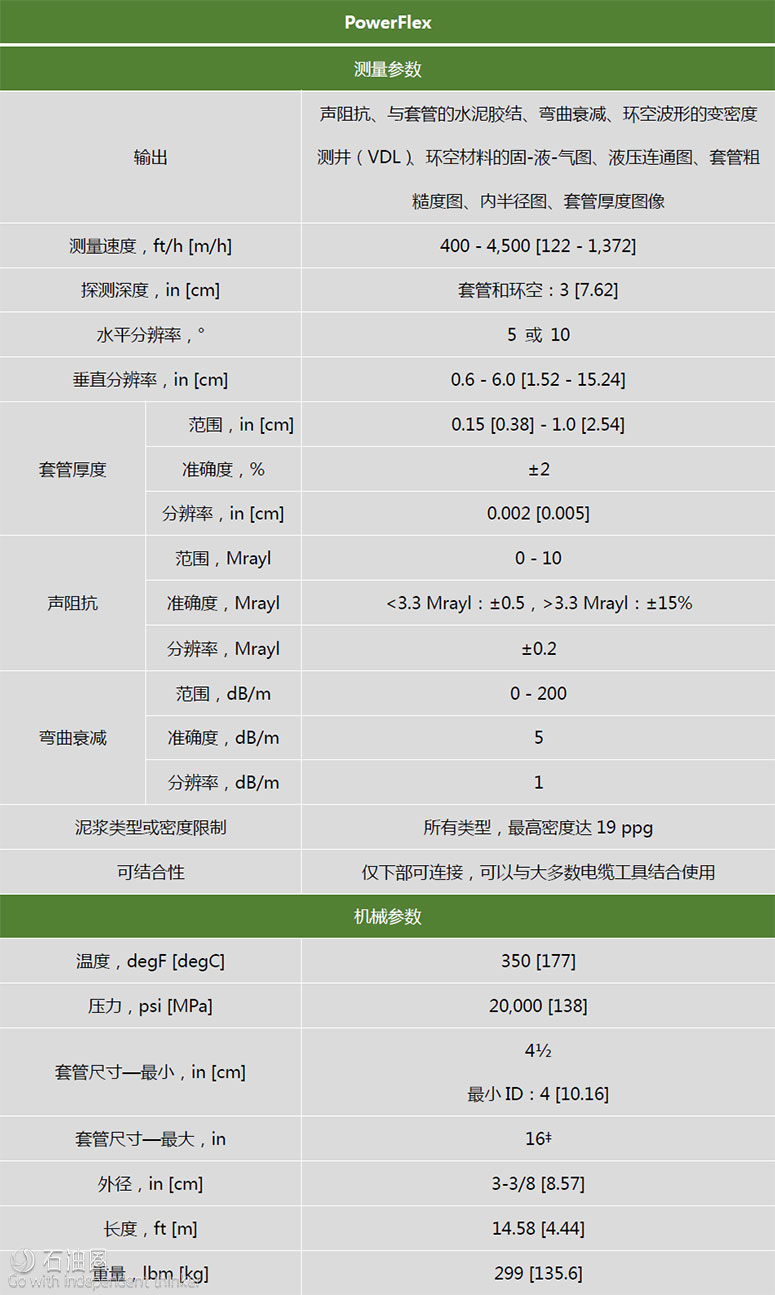

PowerFlex服务:强大的整合技术

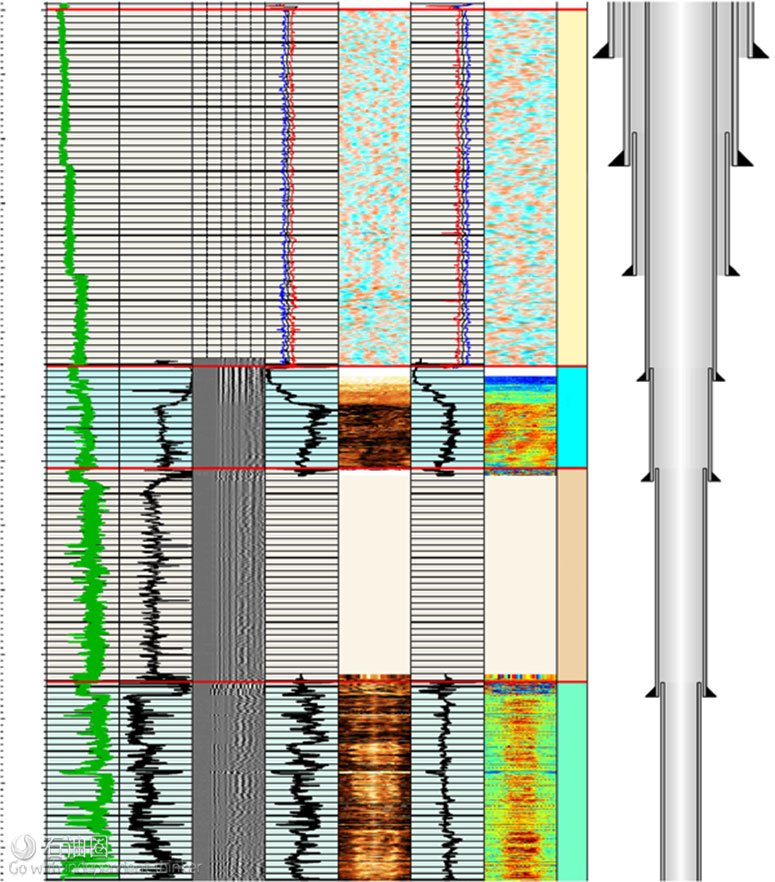

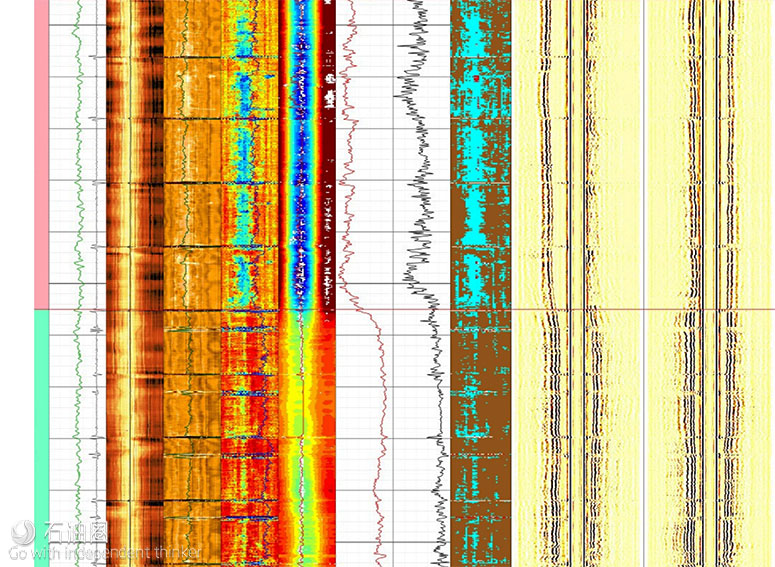

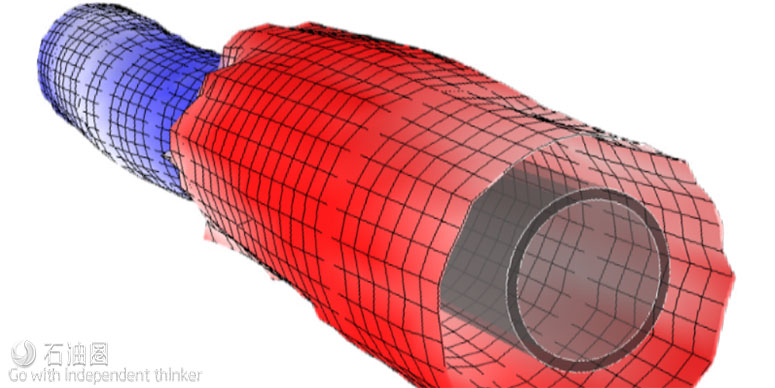

通过同时采集超声脉冲回波数据和进行弯曲波成像,PowerFlex服务可以提供覆盖全方位的套管厚度和水泥的高分辨率图像。PowerFlex服务测量的第三界面回波(TIEs)是唯一能够对偏心套管外壁进行成像的技术。这种对测量数据进行的创新性整合,可以实现对所有水泥类型和密度进行精确、可靠的评价,尤其可以进行识别和量化脱落的水泥,它还利于进行重晶石分层评价。

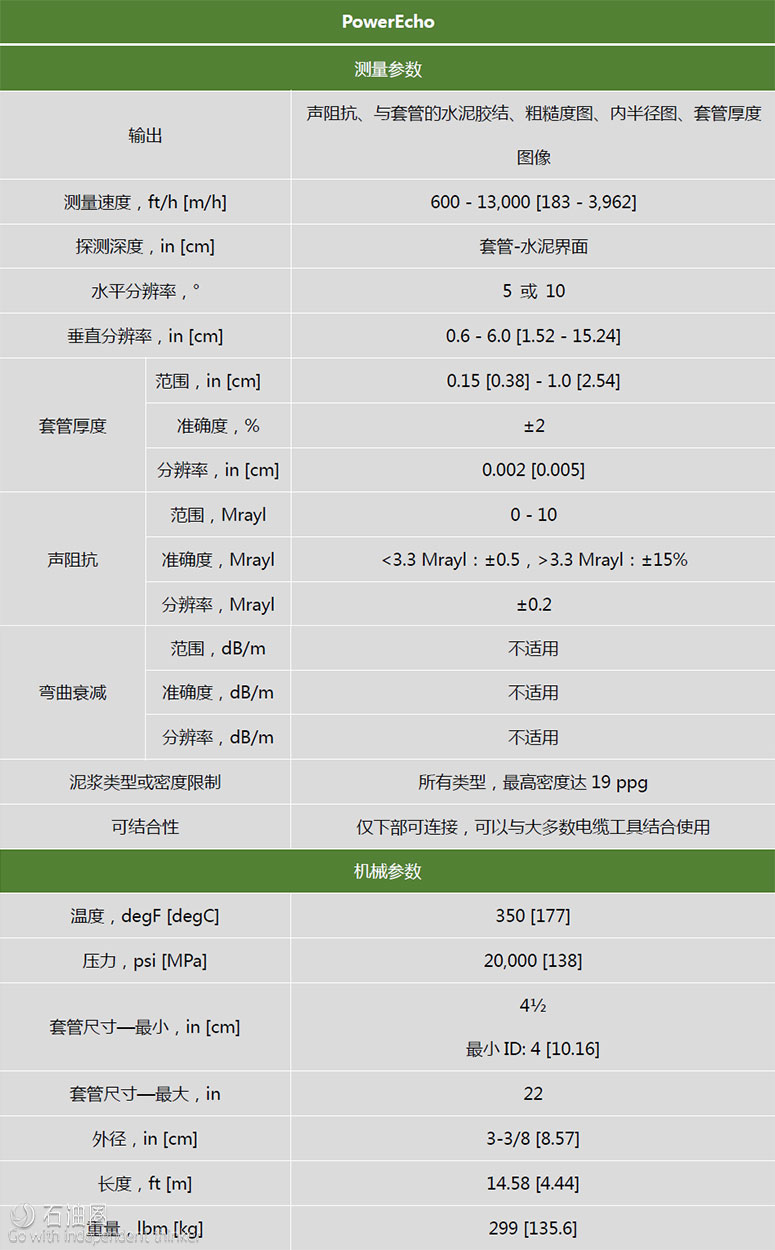

PowerEcho服务:简单直接的测量数据

PowerEcho服务不仅适用于大多数采用常规固井方式的井,也适用于其他采用各种类型和密度水泥固井的井,根据其强大的回波脉冲测量数据,它可以提供套管厚度和水泥的高分辨率图。

采用最新的传感器技术和创新的处理软件和硬件,PowerFlex和PowerEcho服务可以提供那些常规技术无法提供的高分辨率信息。

帮助采纳钻井决策

PowerFlex环空保障措施评价服务可以在设备出井后2小时内提供解决方案。

1.降低评估的不确定性;

2.提高决策的可信度;

3.最多减少50%的测量时间;

4.同时进行套管检查和固井评价;

5.监测钻井时套管磨损,评估破裂压力;

6.避免测井前的流体交换。

PowerFlex服务一次入井,针对4层尾管,以两倍的测量速度,同时评价固井质量和套管磨损,为深水钻井船节约12小时作业时间

帮助采纳固井决策

采用PowerFlex或 PowerEcho服务,针对固井诊断和质量改善进行一次全面的分析。

确认并改善:

1.可靠的固井可视化信息以确认:

-水泥在各个方位的分布;

-足够的套管居中度;

-无窜槽。

2.获得的信息可以改善后续井的:

-水泥分布情况;

-固井质量;

-套管居中情况。

帮助采纳解释决策

在Techlog*井筒软件平台,采用全新的处理、可视化和解释流程,全面综合评估固井水泥层和套管情况。对水泥和套管进行详细、可靠的分析,可以帮助在油井的整个生命周期(从钻井到弃井)进行决策。

1.诊断和理解:

– 采用Invizion*井筒完整性服务进行综合的固井评价;

2.套管居中度和套管接触点;

3.微环隙诊断;

4.渗漏通道分析;

5.破裂和坍塌条件下的套管检测;

6.重晶石分层评价;

7.环空圈闭气。

帮助采纳弃井决策

帮助操作人员在弃井前清楚地理解环空的风险和状况,特别是关键信息不可用的老井。如果不了解如上信息,那么套管的回收、保障措施的移除或安装必将耗时、耗财且频繁出错。

说明并优化:

1.评估并优化套管的回收:

-重晶石分层的间隔;

-套管据中度分析以便做出精确的切割决策,接触点分析。

2.理解环空状况以提高保障措施移除或安装时的操作安全性:

-识别圈闭气;

-评估套管固井质量;

-诊断地层蠕变;

-回收前评估套管状况;

-确认是否有窜槽。

3.弃井流程改进:

-水泥分布质量;

-实施保障措施间隔的选择。

您也有让人挠头的难题需要解决,或是优质技术想要找应用市场吗?如果有的话,欢迎联系小编微信或邮箱,也许能找到一剂良药。

二丫:131-3255-0596;zhanglingyu@raiborn.com

大安:131-3203-1392;lishian@raiborn.com

Assuring the integrity of the well—from well construction to abandonment—is critical to preventing damage to people, the environment, and assets. Catastrophic incidents attributed to the failure of well integrity are the global driver for improvement in the installation and evaluation of barriers. Barrier evaluation must be robust, reliable, and timely in all possible conditions. Only then can it fulfill its critical role in decisions that mitigate risks in current well operations—and help improve barrier installation and performance in the next well.

PowerFlex service—a powerful combination

By simultaneously acquiring ultrasonic pulse-echo measurements and flexural wave imaging, PowerFlex service provides a high-resolution map of pipe thickness and cement with full azimuthal coverage. The measurement of third-interface echoes (TIEs) by PowerFlex service uniquely images the outer wall for pipe standoff. This innovative combination of measurements enables precise, reliable evaluation of all cement types and weights, particularly for identifying and qualifying debonded cement, and excels at barite sag evaluation.

PowerEcho service—a single straightforward measurement

For more conventionally constructed wells—but also performing in all cement types and weights— PowerEcho service delivers a high-resolution map of pipe thickness and cement from its powerful pulse-echo measurement.

With new transducer technology and innovative processing software and firmware, PowerFlex and PowerEcho services deliver high-resolution information where conventional technology cannot perform.

Powering Drilling Decisions

Use PowerFlex annular barrier evaluation service when you need the industry’s best wellsite answers, available within 2 hours of pulling out of hole.

Evaluate and take action

1.Reduce evaluation uncertainty

2.Increase confidence in decisions

3.Cut logging time up to 50%

4.Simultaneously conduct casing inspection and cement evaluation

5.Monitor drill wear and evaluate burst pressure

6.Eliminate fluid swapping before logging

Powering Cementing Decisions

Run PowerFlex or PowerEcho service to conduct a comprehensive analysis for cementing diagnosis and improvement.

Confirm and improve

1.Reliable visualization of the cement to confirm

-azimuthal placement of cement

-adequate pipe centralization

-absence of channels

2.Information to improve the next well’s

-cement placement

-cement quality

-pipe centralization

Powering Interpretation Decisions

Comprehensively evaluate both the cement sheath and pipe condition with novel processing, visualization, and interpretation workflows in the Techlog* wellbore software platform. Detailed and reliable diagnosis of cement and pipe behavior informs decisions across the life of the well, from drilling through abandonment.

1.Diagnose and understand

-Integrated cement evaluation with Invizion* well integrity services

2.Pipe standoff and casing contact points

3.Microannulus diagnosis

4.Leak path analysis

5.Pipe inspection for burst and collapse conditions

6.Barite sag evaluation

7.Trapped gas in the annulus

Powering Abandonment Decisions

Clearly understand annulus hazards and behavior prior to abandonment, especially in older wells where critical information is unavailable. Without this informed basis, pipe retrieval and barrier removal or placement can default to time-consuming and costly trial and error.

Illuminate and optimize

1.Evaluation to optimize casing retrieval

-intervals of barite sag

-pipe standoff behavior for precisely placed cut decisions and contact points

2.Understanding of the annular condition to improve the operational safety of barrier retrieval or placement

-identify trapped gas

-evaluate casing cement

-diagnose formation creep

-evaluate pipe condition prior to retrieval

-confirm presence or absence of channels

3.Abandonment process improvement

-cement placement quality

-interval selection for barrier placement

未经允许,不得转载本站任何文章:

石油圈

石油圈