The subsea processing industry is at a pivotal point as it transitions from mostly niche ‘one- off’ projects to mainstream feld developments, where its value is now largely accepted.

The ethos of subsea processing has always been about moving as much of the conventional processing capabilities from the surface to the seafoor—helping to debottleneck topside facilities and subsea pipelines, increasing recovery rates and, in some cases, creating new possibilities for proftable feld developments.

Technological development has accelerated in recent years, with core technologies such as boosting, separa- tion, power and compression now routinely considered as part of new development scenarios. They also are seen as an opportunity to improve return on investment on aging brownfeld projects.

Gas compression

Subsea gas compression is one emerging technology that can signifcantly improve the economics of many mature gas felds. By placing such systems on the sea- foor, the E&P industry can accelerate production while eliminating the need for costly topside facilities.

GE’s Blue-C technology is at the heart of both its subsea dry and wet gas compression system. Initially designed for dry gas, a wet gas version of the compressor that can handle up to 5% liquid has now been devel- oped, eliminating the need for a subsea separator and resulting in a more compact and lower cost system.

The Blue-C is a high-capacity centrifugal compressor designed for maximum reliability that has undergone exhaustive testing in a submerged environment to ensure full optimization for subsea operation. It can be confgured to run from 4 MW to 20 MW, providing the fexibility to deliver systems for use in both small and large felds or to run with a single compressor or more than one compressor in parallel.

The industry’s first reliable, cost-effective alternative to traditional offshore platforms

GE’s compression solution

The key to successfully pushing subsea production boundaries, particularly for marginal and deepwater fields, is reliable subsea compression. The unit must be capable of continuous, maintenance-free operation for years. To meet this challenge, we have leveraged our rich heritage in compression technology for the toughest challenges – creating Blue-C, the first subsea product in our proven Integrated Compressor Line (ICL).

The Blue-C subsea compression module has an extremely robust design including a single-sealed housing to withstand extreme pressures and temperatures, and a simplified mechanical configuration for reliable unattended operation. As the first technology to take gas compression below the surface, Blue-C is quite literally changing the industry’s horizon.

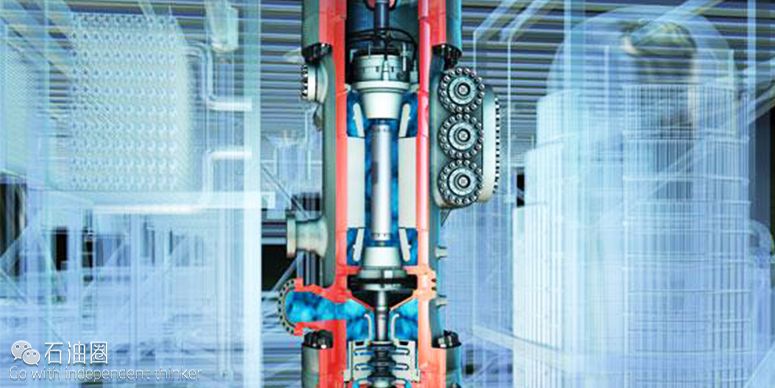

Vertically stacked orientation protects electric motor from raw process gas and drains liquids from the unit. This configuration also reduces the module’s overall footprint .

- Packaged in a single-sealed housing designed to withstand extreme pressures and temperatures

- Robust rotordynamic design with three Active Magnetic Bearings (canned type)

- Driven by a gas-filled, high- speed electric motor to enable autonomous operation

- Diffuser separation system and dust removal device for wet gas compression

- Stainless steel for maximum protection of compressor parts exposed to raw process gas

Making subsea an economic reality

To date, production from marginal subsea and deepwater fields has been hampered by high investment costs. Now a revolutionary, next-generation technology from GE Oil & Gas — the Blue-C subsea compressor — offers a viable alternative for extracting resources that were previously not economically recoverable.

Blue-C is part of our Integrated Compressor Line suite of products and has been specifically designed to reduce the industry’s dependency on topside facilities while enabling greater flexibility in deepwater situations. The subsea units connect directly to shore or distant platforms through subsea flowlines. Installation of subsea gas boosters or re-injection compressors close to the wellhead manifolds will allow operators to enhance productivity and maintain plateau production for an extended number of years.

The compression modules will be available in a power range up to 15 MW, with the same pressure and flow ranges as conventional natural gas compression applications.

The high-tech answer for low-margin wells

The Blue-C subsea compression module consists of a centrifugal compressor driven by a gas-filled, high-speed electric motor, stacked in a vertical orientation and packaged in a single-sealed housing designed to withstand the surrounding hydrostatic pressure.

The significant technical challenges associated with highly reliable yet unattended operation have been resolved through a number of creative engineering solutions.

One of the most notable among them was the elimination of dry gas seals, which are susceptible to damage from sand-gas mixtures and transient conditions. They also require a reliable barrier gas source and regular maintenance such as cartridge replacement and head machining. In short, dry gas seals require too much attention to be reliable in long-term subsea duty. We successfully eliminated them through the use of a gas-filled motor, special materials selection and design procedures specifically developed for this application.

石油圈

石油圈