复合材料是一种通用、稳定的解决方案,可以解决上游油气行业包括海上平台上管道系统面临的诸多问题。

编译 | 影子

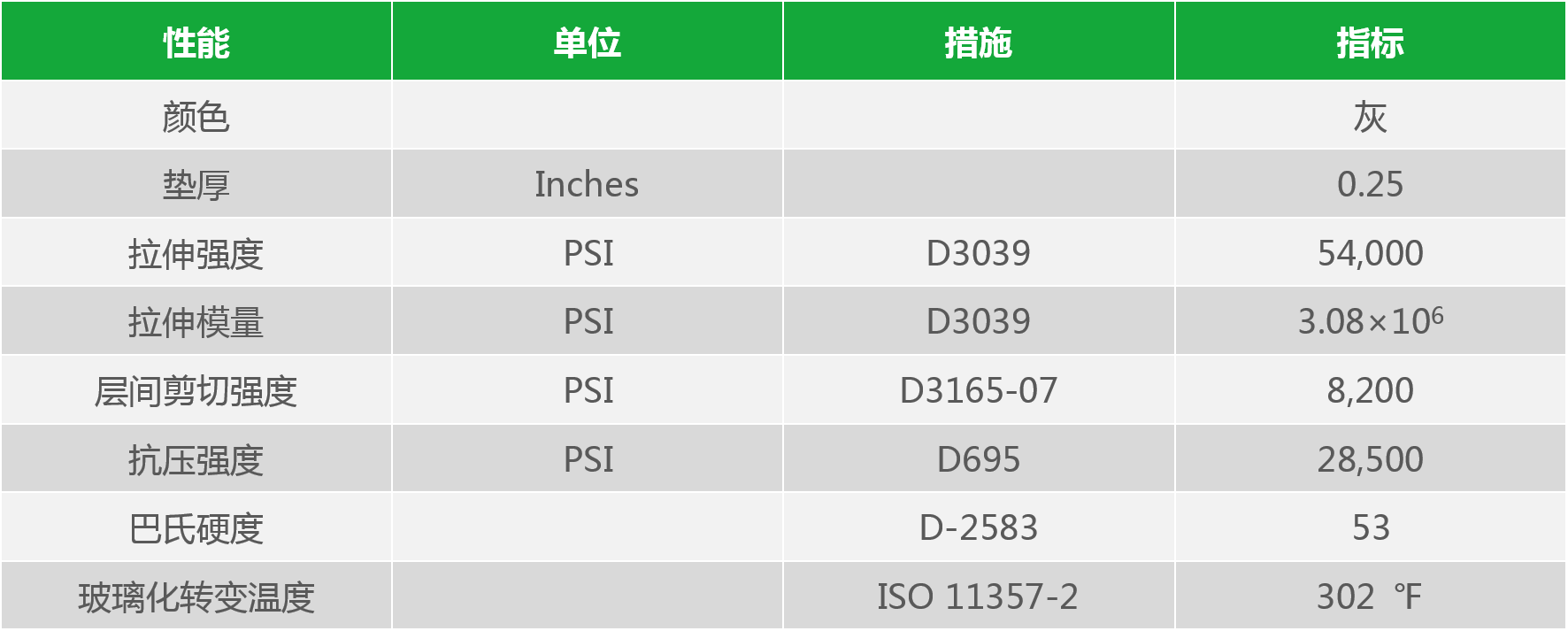

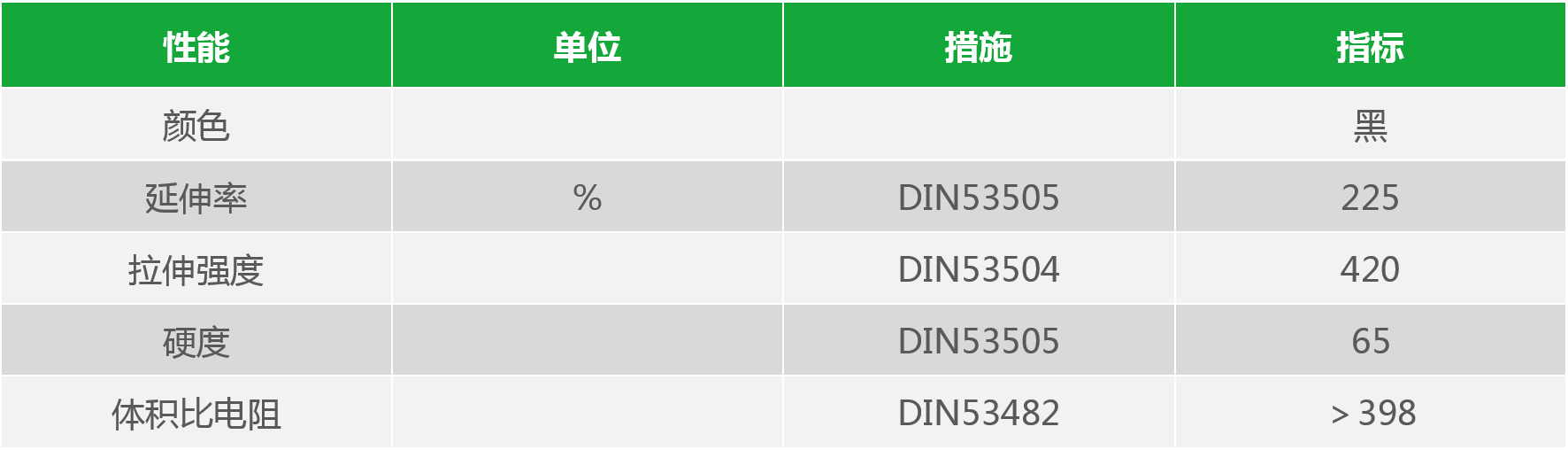

复合材料的工艺适应性较广泛使其能够适应各种情况。纤维为修复材料提供强度和刚度,而树脂则起到保护纤维以及将修复材料粘结在一起的作用。纤维和树脂的不同组合方式可以使复合材料具有不同的性能,从而可以解决各种问题,可以为现有涂层提供机械保护、防止外部腐蚀、或修复因外部腐蚀或其他严重缺陷而损坏的管道。

缝隙腐蚀

潜在腐蚀的一个危险区域是管道与其他物体接触的位置。复合材料可实现应力重新分布,是冲击保护和减振的理想材料。另外,由于轴向运动和振动,会使涂层随时间磨损,进而导致金属之间发生接触。因此,搁置在支撑件上的管道就很容易受缝隙腐蚀的影响,这将导致金属在载体上形成局部侵蚀。

ClockSpring|NRI的技术之一——Pipe Sock™体系,可以有效地预防这种情况发生。该体系由固化的玻璃纤维耐磨垫和弹性粘合剂组成。除了具有高度粘合性能之外,弹性聚合物还具有更高的韧性和弹性,这使其能够承受外部条件,避免了类似环氧基耐磨垫破裂和失效的情况发生。

案例研究:卡箍修复

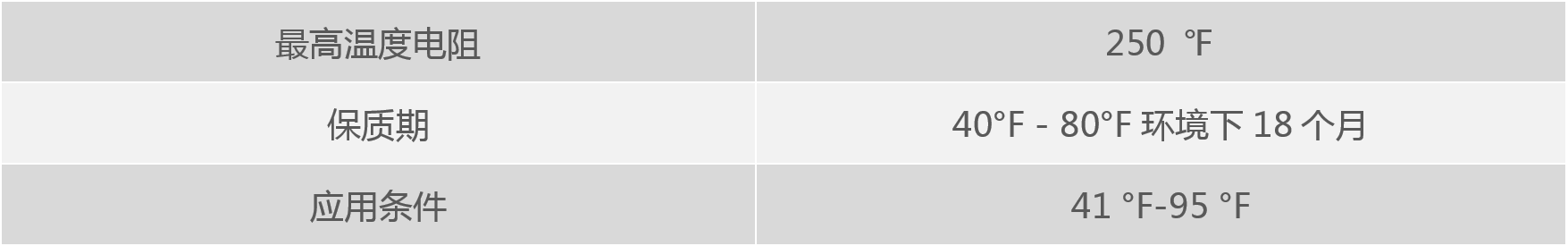

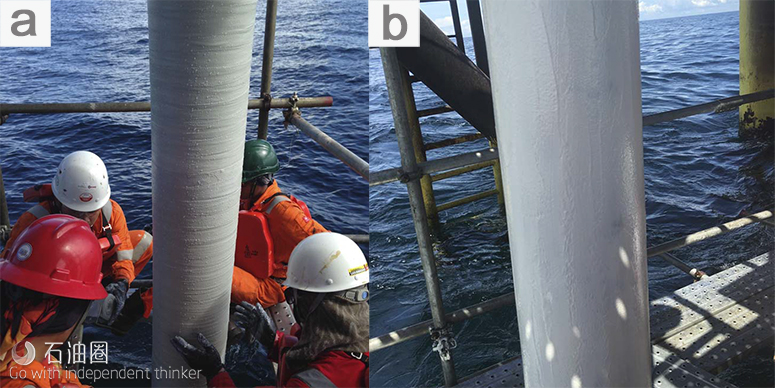

由于与管道支架和卡箍接触,一段6英寸管道形成了常规外部腐蚀(下图a)。除了恢复损失的强度之外,通过复合材料包裹防止与管道支架间的金属接触,最大限度地减少卡箍运动和腐蚀。为了包住卡箍,需要填充螺栓周围的空间以去除复合材料修复下方的气穴和空隙。为达到此目的,提供了一种具有触变性且不下垂的填料,其具有与花生酱类似的稠度并且易于大量施用。在填料凝固后用复合材料包裹,为受腐蚀的管道提供结构性加固,并防止金属与金属的进一步接触(下图b)。尽管也可以用刚性玻璃纤维耐磨垫来防止缝隙腐蚀,但复合材料可以应用于预定方案不实用且不方便实施的独特情况。

修复

另一个操作难点是修复位于溅水区或水下的管道。大多数环氧树脂是亲水的,这意味着它们在较高水分的情况下不能正常固化。对于处于飞溅区域或水下海上设施的许多受损管道而言,这是一个重大问题。因此,应该使用疏水性环氧树脂,因为它的固化不会受到水分的影响,这使其可以在潮湿的环境中使用。

案例研究:溅水区修复

位于东南亚的三根原油立管受到外部腐蚀,需要进行加固。立管上现有的氯丁橡胶涂层已被破坏,并在其下发现了严重腐蚀。作业人员采用 A+Wrap™复合修复体系与SplashBond™底漆对这些立管进行了修复。A+Wrap体系内的聚氨酯可利用水分启动聚合反应,并能在潮湿环境中发挥作用(下图a)。底漆是一种疏水性粘合剂,可去除管道表面的水,并在潮湿条件下固化。修复非常成功,并恢复了腐蚀立管的结构完整性(下图b)。

防护

在防护方面,复合材料最广泛的用途是吸收外部磨损,从而在操作或安装过程中保护管道。使用合适的编织物与硬化树脂相结合可以形成强大的牺牲层,可以防止管道受到任何重大损坏。对于因砂粒或其他碎屑而遭受连续侵蚀的管道,采用复合材料包裹将保护管道和涂层,必要时可方便地添加额外的保护层。

案例研究:冰凌防护

位于美国阿拉斯加寒冷水域海上平台上的立管,很容易受到流入管道内冰片的剧烈机械损伤。A+Wrap体系复合材料采用了橡胶底层包裹和坚硬的外缠绕层,成功分布吸收了来自冰片的能量,避免对底层管道或涂层造成永久性损伤。使用适当的体系可以屏蔽较大的负载和较小的冲击。即使特别具有破坏性的冲击破坏了复合材料,也可以在不干扰底层管道工作的情况下以相对较低的成本进行替换。

结论

复合材料是石油天然气工业管道的一种有效、通用的修复方案。通过使用纤维和树脂的各种组合,可以定制复合材料以适用多种工作和缺陷情况。许多类型的树脂可用于使复合材料更耐化学品、磨损、温度或潮湿环境。不同的织物编织可用于提供更好的防泄漏能力,而织物本身可以提供更大的强度和更好的抗循环疲劳能力,或更好地吸收冲击能量。复合材料可以与现有涂层结合使用,以提供更多的机械保护,防止额外的腐蚀或提供结构加固以修复已经损坏的管道,简单的重涂不能解决这些问题。无论是预防、修复还是保护,正确设计和涂覆的复合材料都可以保护基础设施免受腐蚀数十年之久。

Composites are a versatile and robust solution for many problems facing piping systems across the upstream oil and gas industry, including on offshore platforms. The flexibility of composites makes them adaptable to a range of situations. A composite is made up of reinforcing fibres held together by a thermoset polymer resin. The fibres provide strength and stiffness to the repair while the resin protects the fibres and holds the repair together. Various combinations of fibre and resin can be used to give the composite different properties so that it can address multiple issues, such as providing mechanical protection for an existing coating, preventing external corrosion, or repairing pipe that has already been damaged from external corrosion or other serious defects. Prevention In the case of external corrosion, the adhesive primer component of the composite repair system not only helps the composite adhere to the pipe, but it also acts as a barrier coating to prevent moisture ingress on the pipe. While all composite repairs, when properly performed, prevent further corrosion and protect the pipe, some systems are specifically designed to withstand harsh conditions and be used as a preventative measure. Areas that may require extra corrosion prevention include pipes in heavy salted areas such as offshore locations. Case study: minor external corrosion After the protective coating on a 4 in. pipe section failed, the pipe experienced minor external corrosion. The external corrosion was within the corrosion allowance, thus not requiring a structural repair. However, a composite repair was installed to prevent future coating failure and external corrosion in this congested area, while offering greater mechanical protection to the pipe. The complicated geometry of the pipe section made it ideal for a low width composite repair that can easily conform. Prior to installation, the pipe was cleaned with all rust and scale removed. Once installed, the composite repair was top-coated to protect from UV degradation. Crevice corrosion Another dangerous area for potential corrosion is any location where the pipe is in contact with something else. Composites built for energy absorption and stress redistribution can be ideal for impact protection and vibration dampening. Additionally, pipes resting on supports are susceptible to crevice corrosion due to axial movements and vibrations that will wear down the coating over time, resulting in metal-to-metal contact with the support. This results in the localised attack of metal at the support. One of ClockSpring|NRI’s technologies, the Pipe SockTM system, is designed to prevent this situation from occurring. The system consists of a pre-cured fibreglass wear pad and an elastomeric adhesive. In addition to having high adhesive properties, the elastomeric polymer demonstrates a greater toughness and flexibility, which allows it to survive conditions that would otherwise cause cracking and failures for similar epoxy-based wear pads. Some of the conditions that should be considered when dealing with crevice corrosion include thermal expansion, vibration, axial loads and types of pipe support. Case study: collar clamp repair A 6 in. pipe was experiencing general external corrosion due to contact with a pipe support and a collar clamp (Figure 1). In addition to restoring lost strength, a composite wrap was utilised to prevent further metal-to-metal contact with the pipe support and minimise movement and corrosion in the collar clamp. To wrap over the collar clamp, the empty space around the bolts needed to be filled in to remove air-pockets and voids underneath the composite repair. To achieve this, a thixotropic, non-sagging filler paste was provided that had a consistency similar to peanut butter and is easy to apply in large volumes. After the filler paste was allowed to set, it was wrapped with a composite to provide structural reinforcement to the affected pipe and prevent further metal-to-metal contact (Figure 2). Although rigid fibreglass wear-pads can be used to prevent crevice corrosion, a field applied composite can be applied in unique situations where pre-formed solutions are neither practical nor convenient. Repair External corrosion occurs when a pipe coating fails and the pipe is exposed to moisture. This failure will cause the pipe wall to thin, which reduces its pressure-carrying capabilities. When the damage is severe enough, simply recoating the pipe will not be adequate and it will require structural reinforcement to restore the pressure-carrying capabilities. Composite repairs can be used to restore this lost strength and allow the pipe to operate safely. The design of composite repairs for such structural reinforcement is guided by the equations and methodology in ASME PCC-2 and ISO 24817. The operational conditions of the pipe are important factors in deciding what type of composite to use. Temperature, environmental and chemical resistance, conformance to odd geometry and pipe location must all be considered when determining which system will be effective. For example, high operational and design temperatures will require a thermally-resistant resin with a high glass transition temperature (also known as Tg). Tg is the temperature range at which the resin will transform from a hard and glassy material to a soft and rubbery one, whereupon it will be more susceptible to creep and may be unable to handle the required stress loading. Another operational difficulty is repairing pipes located in splash zones or underwater. Most epoxies are hydrophilic, which means that they will not cure properly in the presence of high-moisture content. This is a significant problem for offshore facilities where many of the damaged pipes are in a splash zone or underwater. Instead, a hydrophobic epoxy should be used because its cure is not adversely affected by the presence of moisture, which allows it to be used in wet environments. Case study: splash zone repair Three crude oil risers located in Southeast Asia were experiencing external corrosion and needed reinforcement. The existing neoprene coating on the risers was damaged and severe corrosion was found underneath. These risers were repaired by using the company’s A+ WrapTM composite repair system along with the SplashBondTM primer. The polyurethane system within the A+ Wrap system utilises moisture to start the polymerisation reaction and can function in wet environments (Figure 3). The primer is a hydrophobic adhesive that will displace the water on the surface of the pipe and cure in wet conditions. The repair was successful in restoring structural integrity to the corroded risers (Figure 4). Additional defect uses Composites can also be used for other defects including, but not limited to, internal corrosion, dents, wrinkle bends and girth weld reinforcements. Leak repairs are the second most common type of defect behind general external corrosion, and they provide their own set of challenges. ASME PCC-2 refers to non-leaking structural reinforcement defects as Type A defects and leaking defects as Type B defects. Instead of only restoring the lost strength to the pipe – as in Type A defects – solutions addressing Type B defects also need to contain the contents of the pipe. The composite can f??a il in three ways: The composite can fail at the bondline and the leak will escape the sides. All these factors need to be accounted for in the design of an effective composite system. Case study: leaking repair on discharge line A 14 in. firewater overboard discharge line was being corroded due to the aggressive sea water environment. Over time, this non-pressurised line developed two large holes causing potential discharge to spill onto the deck. In order to install a composite repair on the line, a stop gap must be used to plug the hole and keep the contents inside the pipe during installation. Clamps and wooden dowels are two commonly used stop gaps, but this repair utilised a quick set putty filler material to plug the hole. The putty has a consistency similar to clay and sets within 5 –10 minutes, forming a seal on the pipe. A composite repair was then applied over the defect to prevent further leaks and external corrosion. Protection Liquid epoxy coatings and fusion-bonded epoxies are two popular anti-corrosion coatings used in the piping industry. Both coatings offer dependable protection from external corrosion due to their good electrical resistance, low water permeability and favourable adhesion strength, but they do not offer much support when it comes to protecting the pipe from mechanical damage. This deficiency means that the coatings are susceptible to being damaged by external forces, which can lead to disbondment and external corrosion of the pipe system. Composites not only perform well as a barrier coating to prevent external corrosion, but the reinforcing fibres also provide strength to the repair, which makes it more resistant to mechanical damage and enhances long-term performance. The most prevalent use for composites in terms of protection is to absorb external abrasion, thereby protecting the pipe during instances of operation or installation, such as high-directional drilling. The use of proper fabric combined with hardened resin can lead to strong sacrificial layers that can prevent the pipe from incurring any major damage. For pipes exposed to continuous erosion due to sand or other debris, a composite wrap will protect the pipe and coating and additional layers can easily be added if necessary. Case study: ice protection Risers on offshore platforms located in the cold waters of Alaska, US, are susceptible to aggressive mechanical damage from ice sheets that flow into the pipes. Using a rubbery under-wrap and a stiffer outer-wrap, the A+ Wrap system composites have been successful in distributing and absorbing the energy from the ice sheets, which results in no permanent damage to the underlying pipe or coating. Large loads and smaller strike impacts can be shielded against by using the appropriate system. Even if a particularly devastating impact damages the composite, a replacement can be made without interfering with the underlying pipeline operations at a relatively low cost. Conclusion Composites can be an effective and versatile rehabilitation solution for pipes in the oil and gas industry. By using various combinations of fibre and resin, composites can be tailored to perform in multiple operational and defect scenarios. Many types of resins can be used to make the composite more resistant to chemicals, abrasion, temperature or wet environments. Different fabric weaves can be used to provide better leak containment, while the fabric itself can be used to provide greater strength and improved resistance to cyclic fatigue or better absorb impact energy. Composites can be used in conjunction with an existing coating to provide more mechanical protection, prevent additional corrosion or to provide a structural reinforcement to repair already damaged pipe that a simple recoat would not address. Whether for prevention, repair or protection, a properly designed and installed composite can be a valuable tool for protecting infrastructure against corrosion for decades.

The leak can work its way through the composite thickness.

The composite can degrade due to chemical attack.

未经允许,不得转载本站任何文章:

石油圈

石油圈