Trendsetter Engineering and Add Energy have combined their expertise in well control engineering and equipment design to develop the relief well injection spool (RWIS).

The RWIS is designed to enable pumping of up to 200 barrels per minute of kill mud through a single relief well utilizing multiple vessels as opposed to the conventional method of multiple relief wells.

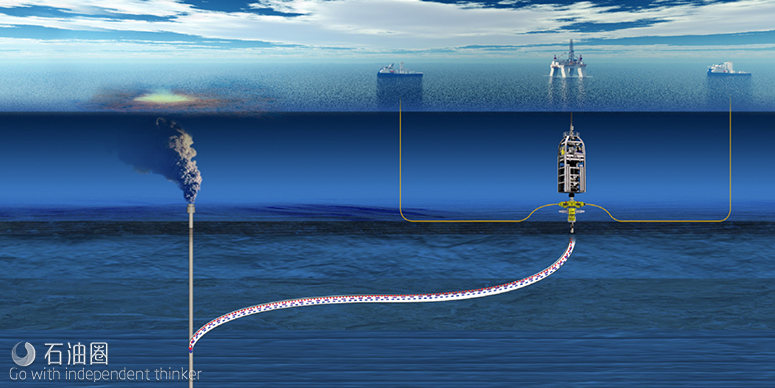

The RWIS is designed to be installed on a relief well prior to intersecting the blowout well and would be positioned between the wellhead and the blowout preventer (BOP), becoming a subsea injection manifold providing additional inlets for pumping kill mud. Each of these inlets is equipped with dual fail-safe barrier valves to provide the necessary means of pressure containment in the relief well. During the well kill operation, one or more high-pressure pumping vessels located near the relief well rig will be connected to the RWIS inlets using high pressure flexible flowlines to provide the additional mud fluid. The RWIS can be rapidly deployed by air, ground and marine freight to any region of the world.

The RWIS has already been requested for specific wells in Norway and U.S.A, and should be available to the market by the end of 2016, the company said.

Since 2010, Trendsetter Engineering and Add Energy have teamed to work together on multiple projects. In 2015, the companies came together with the aim to further develop technology that benefits the energy industry by increasing safety and allowing for more cost-effective drilling operations, resulting in the development of the Relief Well Injection Spool (RWIS). Utilizing both Trendsetter’s subsea engineering experience and Add Energy’s expert on-site advisory for blowouts and well control incidents, the two companies created a breakthrough tool for dynamic bottom kill relief well applications.

The RWIS is a device that increases the flow capacity of a single relief well. In many scenarios, this is a safer and less challenging option to drilling multiple relief wells. The RWIS sits between the relief wellhead and the BOP, and it provides inlets for multiple pumping vessels to hydraulically connect via flexible lines and inject kill fluid into the relief well (see figure). For blowouts where the kill requirements are lower, the RWIS may still provide benefits by allowing a shallower intersect that saves time and limits the spill volumes. In cases where the dynamic kill requirements drive the well design, the RWIS may provide significant savings on the casing, completion and field development.

The Relief Well Injection Spool (RWIS) is a patented specialist subsea equipment that enables operators to stop a blowout from prolific reservoirs safely and efficiently via a single relief well. This is made possible with the RWIS by increasing the pump rate of kill mud into the blowing well by removing the bottle-neck caused by restrictive choke and kill lines from the surface vessel to the seabed.

The RWIS has been designed and built to significantly increase the pumping capacity of a single relief well by pumping in excess of 200 barrels of kill mud per minute through a single relief well, four times as much kill fluid as typically achievable. A significant advance for the industry which utilizes multiple vessels as opposed to the alternative method requiring multiple relief wells.

In addition to the RWIS assuring single relief well contingency, the RWIS also enables operators to optimize well economics and help unlock projects that wouldn’t normally be sanctioned. In purchasing access rights to the RWIS, operators are able to comply with legislation and reduce the number of wells required to meet production targets by increasing the completion size of the well bore, reducing CAPEX costs and maximizing production.

Benefits of using the RWIS:

During project development:

- Complies with legislation and company policy by guaranteeing single relief well contingency

- Enables the completion size of the well bore to be increased, maximizing well flow rates

- Allows production targets to be met with fewer wells, assuring the project can be developed within budget

- Helps to build a business case for project sanction

During a hydrocarbon release:

- Enables rapid kill of a blowing well – through high rate pumping of kill fluids into a blowing well

- Improves safety of a well kill operation through a simplified solution

- Enables relocation of pumping and storage off the rig to dedicated pumping vessels

- Ensures no rig modifications are required or interference with primary well control equipment

- Allows easy mobilization and transportation due to weight and size

PROJECT SHOWCASE

Add Energy was approached by a client who, according to company safety guidelines, requested a blowout-contingency study for an offshore shallow gas well.

A blowout intervention for these types of wells are often faced with many challenges including a narrow depth window to build hydrostatic and frictional pressure during a dynamic kill combined with high pressure differential to balance the reservoir pressure. For a worst-case blowout scenario, using a relief well injection spool (RWIS) may ensure the ability to bring such wells under control with a single relief well.

WHAT WE DID

The Add Energy well-control and flow-simulation specialist modeled the worst-case-blowout scenario using the planned wellbore schematic and predicted reservoir properties. A single relief well with an RWIS installed on its wellhead was used in the simulations to pump kill mud into the target wellbore. Several iterations were made using different kill muds and hardware configurations to achieve a successful kill.

RESULTS

- A worst-case gas discharge of around 3 Billion SCF/Day

- A dynamic kill using the RWIS to pump a heavy mud at a combined rate of 230 bpm

- 50 bpm down primary relief well and 180 bpm down secondary relief well connected to the RWIS

- Hardware configuration was evaluated for hhp requirements, pump curves, pressure ratings, erosional velocities, fatigue limitations, system redundancy and other constraints

- The study demonstrated that a prolific worst-case blowout scenario could in this case be killed with a single relief well

石油圈

石油圈