The IntelliServ™ Network enables instantaneous and bi-directional transmission of downhole data while drilling through Wired Drill Pipe. Rig time is saved as surveys, downlinks, slide orientations and other data-driven activities are performed in a manner of seconds versus minutes with conventional telemetry. Performance limiters associated with logging while drilling (LWD) data density, directional control, well placement and hole cleaning management can be addressed with high frequency and low latency data enabling higher rates of penetration (ROP) to be achieved.

By transmitting the same data required to drill a well, simply faster, drilling time can be reduced by multiple days per well. Find out how many days per well Wired Drill Pipe can save with our Time Savings Calculator.

Wired Drill Pipe enables the next generation of downhole measurements, such as Along String Measurements and TripStar™, which allow other drilling activities such as tripping, hole cleaning, pressure management, and shock and vibration management to be performed faster and more efficiently.

IntelliServ Drill Faster

IntelliServ Wired Drill Pipe enables real-time, bi-directional data which significantly reduces time spent drilling. These time savings are made possible by: Instantaneous survey transmission, faster rotational checkshots, quicker slide orientation, instantaneous RSS tool downlinks, faster LWD data transfer, and faster shock and vibration mitigation.

• IntelliServ WDP has been used to drill over 130 wells, across 30 different rigs and 5 continents.

• During this time the network has delivered value to operators by enabling greater efficiencies to be achieved and wells to be drilled faster.

• Based on the experience gained across these 130+ wells NOV IntelliServ has developed a new generation of the technology, the IntelliServ Network.

• Ground-up redesign of the fundamental network components for:

–Increased reliability and performance;

–Easier operation and maintenance;

–Lower cost of ownership (repair and maintenance).

Drill Faster with WDP

High-speed telemetry provided by Wired Drill Pipe enables real-time, bi-directional data which significantly reduces the time spent drilling, often by three or more days per well.

These time savings are made possible by:

-Instantaneous survey transmission;

-Faster rotational checkshots;

-Quicker slide orientation;

-Instantaneous RSS tool downlinks;

-Faster LWD data transfer;

-Faster shock and vibration mitigation.

Network Controller

Provides easier maintenance and control of the network from surface.

• New IntelliServ Network Controller developed for rigsite operation:

−Simple visualization of network status;

−Activates and records routine network tests;

−Provides status of battery life and signal strength between all DataLinks;

−Outputs downhole data through ethernet/serial;

−Smart diagnostic engine identifies failure modes and provides recommended actions;

−Accessible from 24hr IntelliServ Network Support Center.

Enhanced DataCable

New armouring material provides increased resistance to corrosion and damage.

• New Inconel armoring implemented on DataCable:

−Reduced susceptibility to Stress Corrosion Cracking (SCC);

−Tested in several wells to date;

−Installed in all new Wired DP.

DataLink

Complete redesign of DataLink unit for increased network performance and reliability.

−Battery controller > greater control of battery life;

−Lower cost, wide temp battery pack (-40° /+150°);

−New transceiver board with increased reliability of node-to-node communication;

−Improved shock, vibration and thermal design qualification (Schlumberger standards).

• Provides increased network reliability and uptime.

IntelliCoil™

New coil designs provides increased robustness, durability and reduced susceptibility to damage at a lower cost.

• Next Generation IntelliCoil has been developed to reduce WDP maintenance costs:

• Non-destructive coil removal, reusability, and field installation.

• Simplified coil groove machining:

–Increased robustness.

• Extended coil life.

• Increased tolerance to overtorque/connection damage:

–Reduce damage to coil face as a result of impact.

Case Study1: North Sea Operator

Reduce drilling time in high cost environments with Wired Drill Pipe from NOV IntelliServ.

In today’s high cost offshore drilling environment every hour can be worth tens of thousands of dollars.

Operators are increasingly relying on downhole data to enable accurate well placement, manage ECDs in narrow pressure windows and mitigate shock and vibration. The transmission of this critical downhole data consumes rig time and can introduce performance limiters.

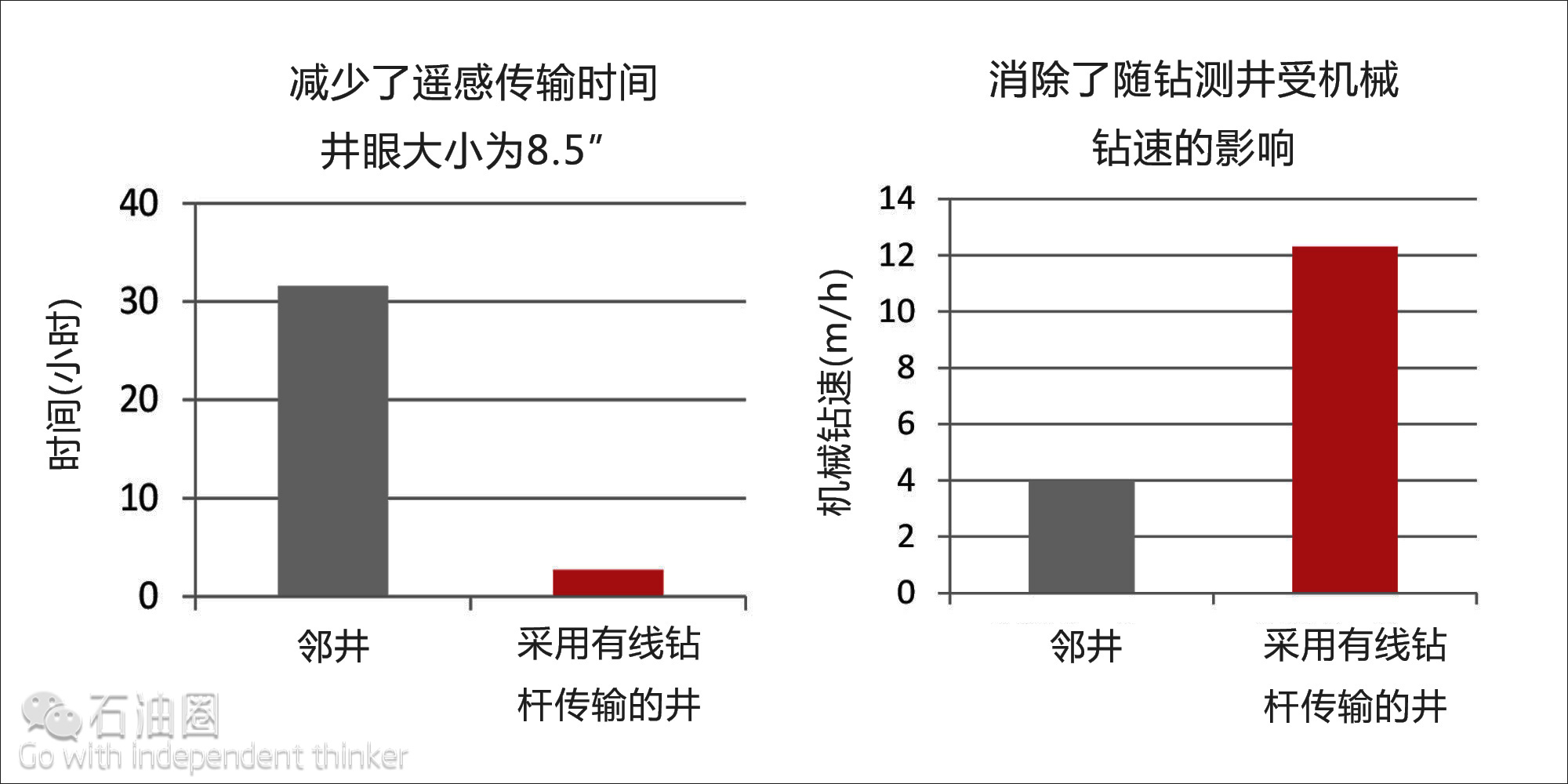

Wired Drill Pipe eliminates this transmission time and ROP limiters with high speed telemetry, typically saving over two days per well.

Wired Drill Pipe eliminates this transmission time and ROP limiters with high speed telemetry, typically saving over two days per well.

Eliminated LWD ROP Limits

• Recorded quality LWD data in real-time without ROP limits.

• 300% increase in ROPs enabled by eliminating LWD ROP limits.

• Drilling time reduced by 9.5 days per reservoir section.

Total of 10.7 days saved per reservoir section.

Case Study2: Norway Operator

Reduce stationary time in high cost environment with Wired Drill Pipe from NOV IntelliServ.

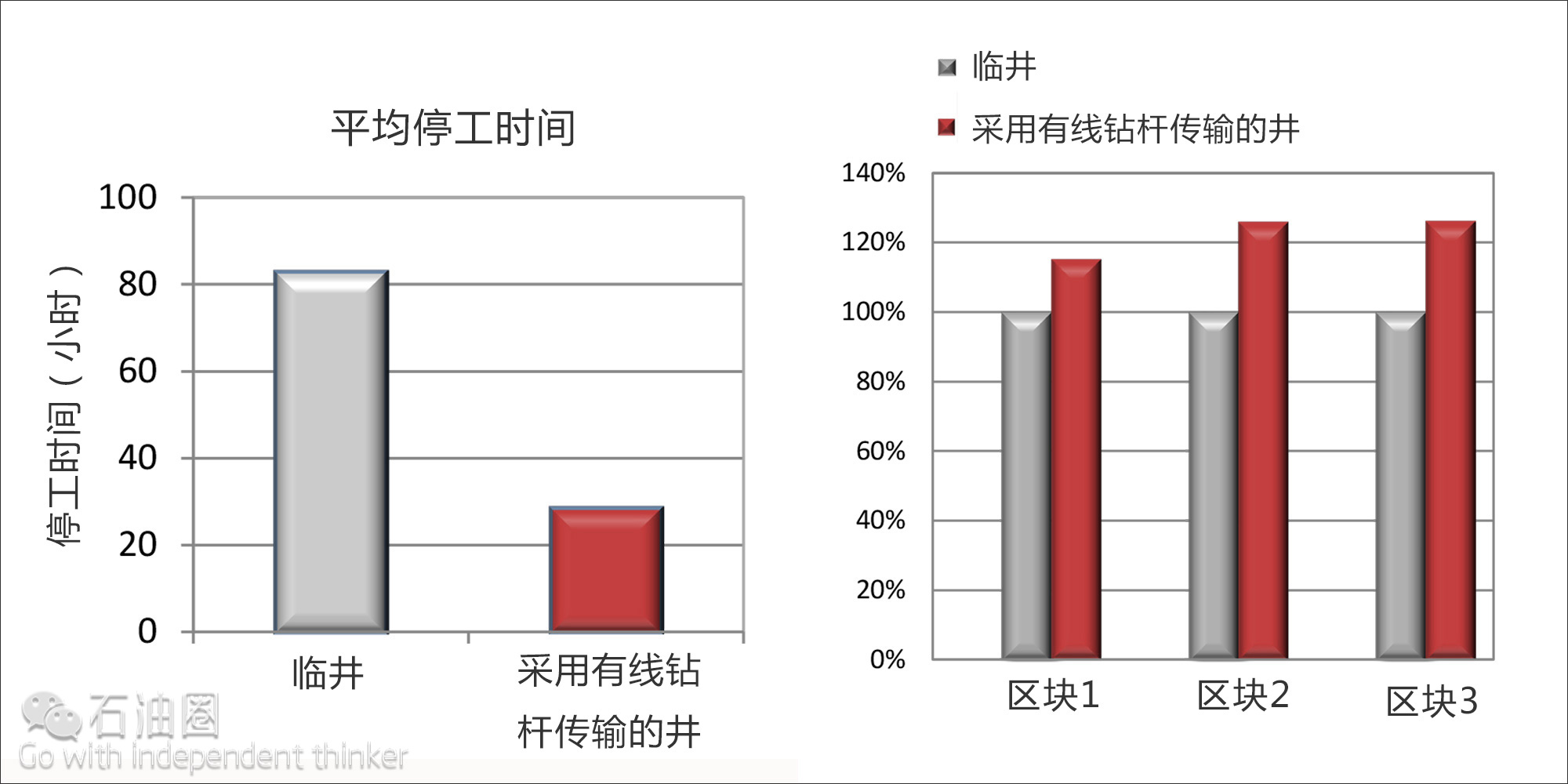

Wired Drill Pipe (WDP) technology was implemented on a multiple well project offshore in the North Sea. The planned wells were so-called “extended J profile wells”, high-angle wellbores with long horizontal displacements and had an average well depth of 18,000 feet.

The aim of this project was to keep the well for a long distance in the most productive section of the reservoir. Typical problems associated with this type of operation include: torque and drag limitations, hydraulics and hole cleaning, vibration and wellbore stability, ECD management, mud rheology, and solids control, and many others.

IntelliServ created a high-speed data network by wiring conventional drill string. This data network enabled quality, real-time recorded (memory) data to be available at surface. In addition, the network was bi-directional in nature which enabled instantaneous and continuous control of downhole tools from surface.

The operators’ objectives from the use of WDP technology were to increase drilling efficiency, decrease the stationary time and lower the overall drilling costs.

Stationary Time & Data Transmission Time

• Instantaneous transmission of Gyro/ MWD surveys, ECD data, MWD/ RSS downlinks, downhole vibration and LWD data.

• Decrease in downhole tool failures.

• Stationary time was reduced by 1.6 days/ well.

Drilling Efficiency

• Recorded quality LWD data in real-time without ROP limits.

• Increased ROPs enabled by eliminating LWD ROP limits.

• Dilling time reduced by 1.1 day/ well.

System Maintenance Time

• WDP regular system maintenance time was found 0.5 days/well.

Final Results

The WDP technology was deployed successfully and operators’ expectations were achieved, delivering an average net time savings of 2.2 days/ well.

Summary

•IntelliServ Wired Drillpipe enables increased drilling efficiency and reduced well time to be delivered more reliably and cost effectively;

•Equipment and service now available through conventional industry supply channels;

•New sizes and configurations enable use on almost all drilling applications.

石油圈

石油圈