The Halliburton CoilCommSM coiled tubing communication service provides a real-time approach to help maximize well-production performances and the success rates of interventions. With CoilComm services, you have the access to accurate depth correlation and temperature and pressure profiles identifying which zones are benefiting from a stimulation treatment and which are being bypassed in a single trip. For jetting and underbalanced operations, you can measure the fluid top and optimize the quantity of injected product, effectively reducing costs.

The measurement spectrum allows for a significant amount of data which can be transferred to surface in real time, and the distributed temperature sensing (DTS) and distributed acoustic sensing (DAS) equipment—when used together—can provide invaluable information on near-wellbore events through simultaneous thermal and sound-field analysis, as well as energy-distribution interpretation.

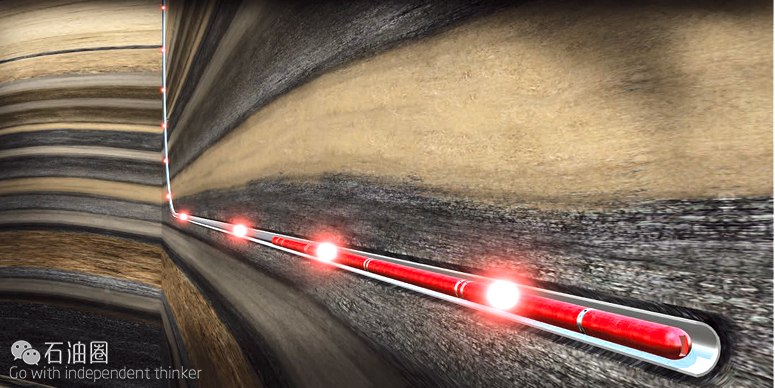

With the uniquely engineered CoilComm service, the optical fiber can be installed inside various coiled-tubing sizes depending on wellbore requirements. More conventional deployment methods can require permanent, casing-conveyed, or tractor-in conveyance, which can be expensive, limited, and risky. Deploying fiber-optic sensing technologies in coiled tubing is a more efficient and economical method for continuous real-time monitoring of horizontal well conditions.

The collar locator, temperature and pressure sensors for localized data acquisition at the bottom-hole assembly (BHA) are validated industry-wide and able to withstand all expected and desired downhole conditions.

CoilComm services provide the following real time data:

- Pressure inside and outside the BHA

- Temperature inside and outside the BHA

- Casing collar locator

- System configured for DTS and DAS

The CoilComm monitoring service provides:

- Real-time fiber optic monitoring down the wellbore

- Improved confidence and safety margins during execution

- Time-saving interventions

- Treatment optimization against outdated and dangerous “rules of thumb”

CoilCommSM services can help:

– Identify which zones are benefiting from a stimulation treatment and which are being bypassed in a single trip

– Provide a full understanding of what is actually going on below the surface, as a detailed snapshot or as a more comprehensive trend over a certain period of time

All of the above has a huge impact on the effectiveness of coiled tubing interventions. Imagine how important it is to monitor the pressure drop across a flow-thru tool in order to achieve proper operation of internal components. Coupled with punctual data acquired at the BHA, the CoilComm™ fiber optics system provides a full understanding of what is actually going on below the surface, as a detailed snapshot or as a more comprehensive trend over a certain period of time.

Depth can be accurately controlled with the casing collar locator, eliminating doubts on where to perforate or set a packer.

Chemical effectiveness, acid corrosion rates and many other temperature-related properties can be maintained within safe operating ranges through downhole temperature control.

Moreover, the CoilComm system is invisible to regular coiled tubing operations: no impact on overall equipment weight, pumping rates or ball drop capabilities are maintained, and multiple fluid types can be pumped without altering standard operational parameters. CoilComm technology relies on the most relevant fiber-optic properties: the capability to act as data carriers as well as direct sensors for several parameters. Encapsulated in a tube-in-tube INCONEL® 1 alloy housing, they provide reliability and long-lasting performance, even in extremely harsh environments.

Taking ownership of coiled-tubing interventions is no longer a compromise. Historically, electric lines deployed inside the coil have filled the gap in getting real-time information from downhole tools. However, these e-line equipped CT strings have their limitations.

CoilComm services solve those drawbacks

Maximize well production performance and intervention success rates with CoilCommSM services.

CoilCommSM service monitoring capabilities include distributed fiber sensing technologies such as distributed temperature sensing (DTS) and distributed acoustic sensing (DAS).

With the uniquely engineered CoilCommSM service, the optical fiber can be installed inside various coiled tubing sizes depending on wellbore require- ments. More conventional deployment methods can require permanent, casing-conveyed, or tractor-in conveyance, which can be expensive, limited, and risky. Deploying fiber optic sensing technologies in coiled tubing is a more efficient and economical method for continuous real-time monitoring of horizontal well conditions.

Know which zones are being effectively treated with StimWatch® stimulation monitoring service.

StimWatch® service—part of Pinnacle’s FiberWatch® service portfolio—uses distributed temperature sensing (DTS) in real time to monitor acid treatments and fracturing treatments to observe stimulation fluid entry points into the formation. This technology gives operators the ability to evaluate fluid entry effectiveness as the well is being stimulated. By monitoring the treatment in real time, operators have the opportunity to make rapid changes to a treatment and ultimately optimize the results.Tracking temperature in the wellbore indicates the velocity and depth of a fluid, indicating which zones are being effectively treated.

CASE 1 Halliburton integration solves problem and saves money for customer.

In Mexico, Halliburton used their CoilCommSM monitoring service to provide real-time fiber optic monitoring as part of an integrated coiled tubing solution that included StimWatch® monitoring service injection analysis by Pinnacle. Working together, Halliburton, Production Enhancement, and Pinnacle engineers and technical advisors provided an integrated state-of-the-art solution that proved highly effective in optimizing both costs and efficiency.

The integrated solution was for a highly deviated well in a carbonate reservoir with a BHT of 140 C (284 F). Real-time monitoring was required as part of the overall reservoir management strategy. Halliburton’s CoilCommSM service provided ideal conveyance for the StimWatch® distributed temperature survey (DTS) service. In DTS, the fiber optic served as the sensing element. When combined with the coiled tubing conveyance and casing collar locator, pressure, and temperature (CPAT) tool, the operator was able to continuously monitor wellbore temperature across the entire horizontal.This was achieved while pumping a stimulation job consisting of acids and diverters, and making real-time decisions based on actual measured injection profiles.

The well was completed with 675 meters (2,214 feet) of 41⁄2-inch liner and swell packers, with 150 meters (494 feet) of tubing conveyed perforations distributed in six intervals.The CoilCommSM service provided accurate monitoring to the stimulation job pumped through the annulus.

CHALLENGES SOLUTIONS RESULTS

- Horizontal well seeming depleted

- Highly conductive natural fractures stealing injection fluids

- Diversion technology needed to be fine-tuned

- Need for multiple service integration

SOLUTION

- Combination of services enabling continuous monitoring and real-time decision making

- CoilCommSM monitoring service

- Distributed Temperature Survey

RESULTS

- Thief zone discovered in real time

- Treatment modified

- Final acid stages cancelled

- Customer saved $120,000 in fluids

- Real-time monitoring planned for additional wells

石油圈

石油圈