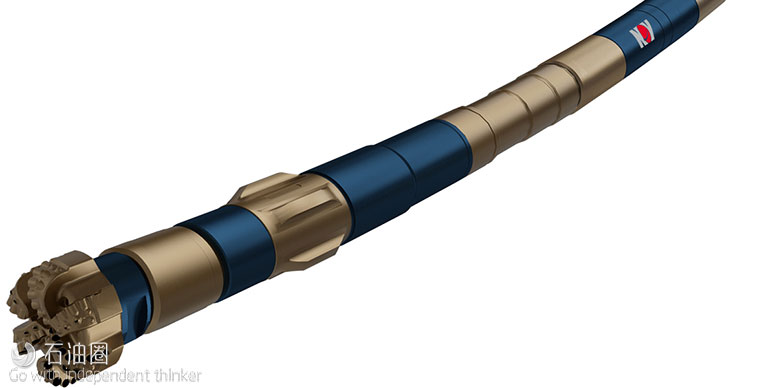

BlackStream EMS StreamThru Tools

The StreamThru variant of the BlackStream™ enhanced measurement system (EMS) family of drilling data acquisition tools, available in both 6.75- and 8.25-in. sizes, is similar in footprint, physical design, sensors, and data-capture techniques to the traditional BlackStream EMS tool.

Description

The BlackStream EMS StreamThru tool incorporates an IntelliServ™ coil on the lower (pin) connection, while previous variants only had a single coil embedded within the tool’s box connection, which effectively blocked the wired drillpipe network to any tool located below the EMS. The addition of a bottom coil enables combined parallel telemetry of the BlackStream EMS StreamThru tool data and any secondary wired drillpipe-enabled tools’ data to surface for use by the rig crew or applications. This breakthrough eliminates the prior design limitation of EMS tools becoming the end of the wired drillpipe network due to their lack of bottom connection. Additionally, it represents a major step forward in allowing not only combinations of multiple BlackStream tools to be run in series along wired drillpipe but also placements of other third-party wired drillpipe tools.

Features/Benefits

(1)Allows for parallel memory recording and real-time telemetry via the IntelliServ wired drillpipe network

(2)Transmits data to surface at rates up to 80 Hz

(3)Records statistical data (maximum, minimum, mean, standard deviation) to memory every 2.56 seconds

(4)Records downhole weight, downhole torque, two-axis bending, rotation, three-axis vibration, annular pressure, internal pressure, and temperature

(5)Recording data can lead to mitigation/optimization of events such as weight transfer, stick-slip, and wellbore tortuosity

(6)Available in two material varieties for application specific needs:

Standard nonmagnetic material applications

H2S “sour service” gas drilling applications

BlackBox/BlackStream 6.75-in. EMS Tool

The 6.75-in. BlackBox™ and BlackStream™ EMS tools, available in either memory recording or IntelliServ™ data streaming configurations, are capable of an array of measurements including multi-axis vibration, load, pressure, bending*, and rotation. Our collar-based EMS tool can help us deliver custom solutions for drilling challenges such as stick-slip, whirl, and borehole quality to optimize drilling performance and reduce well delivery costs. BlackBox downhole dynamics data is stored in memory for detailed analysis at the surface. Surface data acquisition, visualization, and software analysis capabilities provide well construction teams with the information to optimize performance.

Available measurements:

Weight

Torque

Bending*

Annular pressure

Internal pressure*

Three-axis vibration

Rotation

Temperature

* Measurements available on certain configurations

Features/Benefits

Proprietary and patented depth/pressure compensation

Ensures the highest accuracy of weight and torque measurements

Maximum, minimum, and mean values for load measurements statistically recorded at up to 800 Hz

Delivers accurate data resolution—visualize trends in downhole behavior and identify key optimization methods

Short, versatile ~9-ft sub length

Allows for versatile placement in the BHA or drillstring— flexibility to collect data from various locations

IntelliServ™ compatible

Allows for “real-time” streaming of downhole data when utilized with wired drillpipe

Not dependent of additional downhole equipment for power or communication

Allows for increased tool placement options for data capture

Self-contained power supply

Allows tool to be run independent of other downhole equipment

BlackBox/BlackStream 8.25-in. EMS Tool

The 8.25-in. BlackBox™ and BlackStream™ EMS tools, available in either memory-recording or IntelliServ™ data streaming-configurations, are capable of an array of measurements including multi-axis vibration, load, pressure, bending, and rotation. Our collar-based EMS tool can help us deliver custom solutions for drilling challenges such as stick-slip, whirl, and borehole quality to optimize drilling performance and reduce well delivery costs.

Available measurements:

Weight

Torque

Bending

Annular pressure

Internal pressure

Three-axis vibration

Rotation

Temperature

Features/Benefits

Proprietary and patented depth/pressure compensation

Ensures the highest accuracy of weight and torque measurements

Maximum, minimum, and mean values for load measurements statistically recorded at up to 800 Hz

Delivers accurate data resolution—visualizes trends in downhole behavior and identify key optimization methods

Short, versatile 15-ft sub length

Allows for versatile placement in the BHA or drillstring— flexibility to collect data from various locations

Nonmagnetic tool

Reduces interference with directional equipment and increases tool placement options for data capture

Self-contained power supply

Allows tool to be run independent of other downhole equipment

石油圈

石油圈