As deeper and more complex well designs proliferate throughout oil and gas fields, well completion methods are challenged and new technologies are emerging to ensure safe, cost efficient, and optimized completions.

The Welltec Flex-Well completion concept is a flexible, single-skin (monobore) system that allows fit-for-purpose completion designs that can be as minimal or intricate as needed for optimal reservoir drainage and do not require the use of cement or swellable packers.

Reliable and effective annular barriers continue to be crucial to well management for safety and performance. Cementing has been the industry’s conventional means of creating these barriers, having been used for almost 100 years (American Oil & Gas Historical Society 2015). However, the industry is not drilling and completing wells the way that it did a century ago.

The advances in drilling, particularly those related to horizontal well technology, have led to well designs and completion environments that often exceed the capabilities of cement to provide a reliable annular barrier that will last as long as the well. Efforts to overcome the challenges of many of today’s wells with cement can lead to complicated, expensive, and time-consuming operations.

The use of certain swellable packers has arisen as an accepted alternative, primarily because of time savings. However, their degradable polymer content has a significant risk of failure in harsh downhole well environments. Wells with swellables have been shown to leak approximately 50% of the time after 5 years from the time of installation.

With more than half of the world’s rigs drilling highly deviated or horizontal wells, and an increasing number of mature fields with depleted well zones, the challenges of such wells call for barriers that not only are cost-efficient but will also remain effective throughout the well’s lifetime.

Expandable Annular Barrier

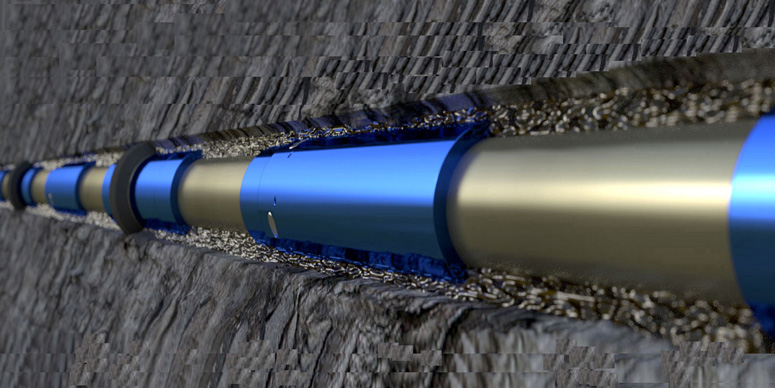

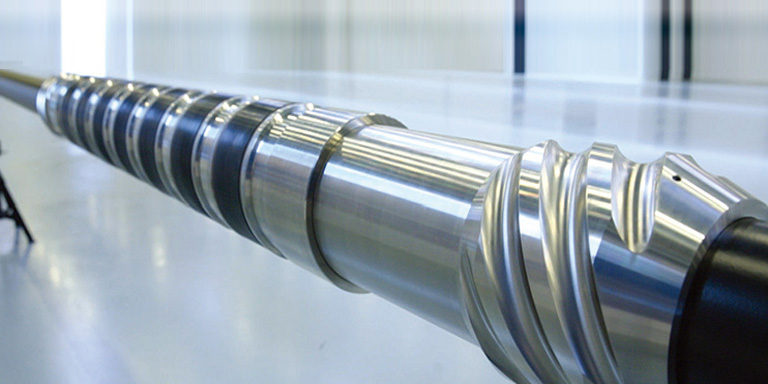

A key component of the flexible, single-skin completion system is the Welltec Annular Barrier (Fig. 2), an all-metal expandable barrier with a large expansion ratio that was developed for a wide variety of applications in well construction, including well integrity and zonal isolation. Designed for the specific well during its construction phase, before the well is spudded, the barrier delivers reliable annular isolation and maximizes the ability to handle pressure change across the entire borehole, without internal restrictions, over the life of the well.

The all-metal barrier is designed to address many of the drawbacks of conventional completion methods, including swellable packers, in short- and long-term time horizons and extreme environments. The installation takes considerably less time, and it allows for early production because there are no swellable elastomers with a waiting period for setting.

Qualified to ISO 14310 V3 testing as standard practice, the all-metal barrier also has been qualified to V0 in some sizes. The barriers have been developed and used as a primary barrier for well integrity, replacing cement and in one case preventing surface annular pressure buildup in a field where previous conventional methods used to achieve isolation had failed.

Typically inflated from the surface, the all-metal barrier allows for reservoir control and restimulation of multiple zones stretching horizontally over a distance of more than 30,000 ft. It is a unique, single-skin well completion liner, assembled on the outside diameter of the base pipe while maintaining full-bore inside diameter (ID).

The all-metal barrier provides long-term, robust, and reliable zonal isolation in cemented and uncemented wellbores and may be used in conjunction with casings and liners. Because there is no compromise to the ID, the barrier does not impair or restrict flow conditions, thus allowing well maintenance to take place quickly and easily.

Cementless completions using the all-metal barrier technology hold a number of advantages, namely:

Well construction cost savings in materials, logistics, and time;

Reduced risks of channels and leaks developing in the barrier;

Reduced skin damage in the formation zone(s) of interest;

Continued barrier pressure protection during well plugging and abandonment, thus eliminating guesswork about pressure levels and leakage dangers.

Uncured Cement Application

As required in some regulatory regimes, the all-metal barriers can also be set in uncured cement to provide cement assurance. They are installed as part of the liner or casing string and positioned at depths where cementing is deemed difficult. The liner (or casing) is hung off and the cement operation completed as is normally done.

When setting in uncured cement, while the cement plug is being bumped, additional pressure is applied to the well to expand the well annular barrier. The hydraulic expansion in the wet cement ensures conformance to the open hole and eliminates the risk of cement channels that could compromise isolation.

The risk of a microannulus forming between the casing and cement is removed. Controlled expansion extrudes the cement away, leaving only a barrier-to-formation or a barrier-to-casing contact.The relative high plasticity of the formation in comparison to the steel will ensure that steel-to-formation contact remains after the release of the expansion pressure.

Any cement trapped between the barrier and the formation will not experience the relaxation of pressure when the drilling mud is displaced, hence removing potential microannuli and deterring the migration of fluid or gas behind the cemented casing and liners.

Lower Completion Deployment

Another driver for the flexible, single-skin completion concept is the ability to swiftly and safely deploy an entire lower completion. This capability is possible because the single-skin completion functions as a solid liner. As there are no control lines needed, the installation is fast, efficient, and easy to place in the laterals.

The hardware is sufficiently rugged to allow rotation, which is often required in extended reach wells during installation. And the solid liner’s capability provides the option to “float” the completion in, using buoyancy if needed to reduce friction against the wellbore.

The fullbore, solid liner also helps to ensure safe well abandonment when required, aided by the preinstalled well integrity barriers located exactly where required.

Reservoir Compartments

An additional advantage of the flexible, single-skin completion is the ability to use the all-metal barriers and well flow valves to construct a number of controllable “compartments” (Hazel et al. 2013). The flow valves are installed as required within each compartment, which can be designed for stimulation injection or production to accomplish the completion objectives.

Frequently, the reservoir quality changes over the length of the lateral, either as a natural occurrence or as part of the well placement. The flexible, single-skin completion concept reduces the risk by offering a potentially unlimited number of zones across the reservoir. And these zones can be opened or shut to optimize production and reservoir drainage.

Having discrete compartments that can be controlled individually enables early production and helps to increase ultimate recovery. The total well production, the water production, and gas breakthroughs can all be managed as they occur, without the need for a rig based, well workover. The design affords the operator the complete control of the reservoir, enabling reductions in operating expense.

石油圈

石油圈