AccessFracSM suite of services helps achieve improved longterm production and extend the economic life of virtually any hydrocarbon-producing asset in which fracturing treatments are performed. The service typically incorporates one or more of the following components:

1.A unique new chemical diverter system;

2.Proppant coating technology;

3.Polymer alloy proppant;

4.Special fluid and treatment design, and pumping schedule.

The AccessFrac services are particularly appropriate for low permeability formations, especially shale . AccessFrac service can result in increased stimulated reservoir volume and greatly improved reservoir contact through two processes:

TreatmentsTailored toWell Requirements

AccessFrac service is available in different configurations that can be customized to help achieve improved long-term production.

AccessFrac PD service is designed to improve proppant distribution in multi-zone completions, helping make sure all perforation clusters are treated. The service can help make perf and plug and sliding sleeve-based treatments more efficient.

AccessFrac RF service is designed for refracturing treatments. The service enables sealing off existing perforations in order to stimulate bypassed and new intervals.

AccessFrac CF service is used to enhance the development of complex fracture networks often created in shale formations. The additional fracture network complexity will help improve the ultimate hydrocarbon recovery and daily production rates.

Helps Solve Costly Problems

AccessFrac service addresses two challenges operators often face in producing hydrocarbon from ultra tight formations like shale:

1.Rapid production decline following fracture treatments;

2.Uneven proppant distribution in plug-and-perf operations due to most of the proppant going into the fractures nearest the downhole plug. In addition to reduced production, this can lead to using excess proppant and fluid to try to compensate for the uneven proppant placement.

Technical highlights

New Multi-Zone Completions

In new multi-zone completions, AccessFrac service can significantly reduce completion time compared to conventional fracturing techniques such as plug-and-perf. Also, improved reservoir contact can result in more initial and long-term production.

Refrac Treatments

In refrac treatments, AccessFrac service provides an unprecedented ability to seal off existing perforations in order to perforate and fracture new zones. And the connected volume of existing fractures can be increased for better reservoir drainage.

Problem Wells

AccessFrac service has proved very effective in fracturing wells with conditions that make it impossible to insert plugs in the wellbore.

UniqueTechnologies Enable AccessFrac Service

In addition to the critical treatment design, pumping schedule and specialized fluid design, AccessFrac service includes a diverter and may include other technologies.

Degradable Diverter System

AccessFrac service can include a proprietary degradable diverting material in the near wellbore region and, when appropriate, within the formation. The material is the first degradable chemical diverter that can withstand the rigors of fracturing. The diverter can be used to create a temporary blockage that will degrade entirely with time requiring no special solvents or additional surface operations. The new BioVert? diverting material, often used in conjunction with AccessFrac service, is sourced from the food industry meaning it adds another layer of environmental protection to personnel and wellsite operations.

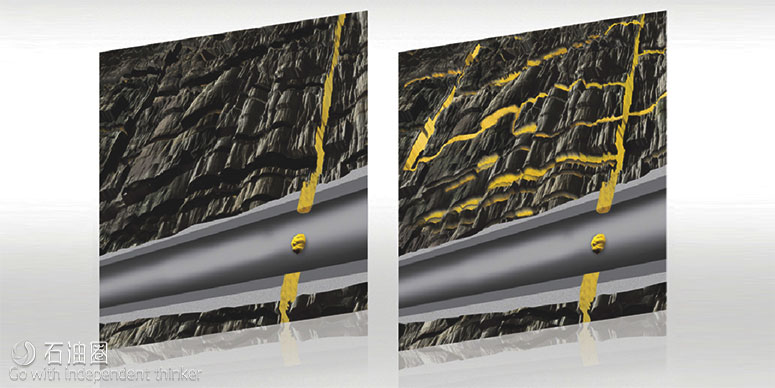

SandWedge ABC Conductivity Enhancer

The AccessFrac process can include SandWedge? ABC enhancer to help achieve and sustain a more conductive proppant pack. In addition, coating the proppant with SandWedge ABC enhancer is instrumental in placing proppant pillars to achieve infinite conductivity in certain formations. Also, the enhancer protects against plugging due to intrusion of formation material.

MonoProp Low Density Proppant

This new polymer alloy proppant provides a method to achieve a partial monolayer of proppant inside the fracture. Placing a partial monolayer of proppant results in very high fracture conductivity, which can lead to improved production. The low density of the proppant makes it easy to place with low viscosity fluids while providing uniform distribution. MonoProp proppant deforms and maintains a conductive path while conventional proppants tend to crush and produce fines when exposed to closure stress.

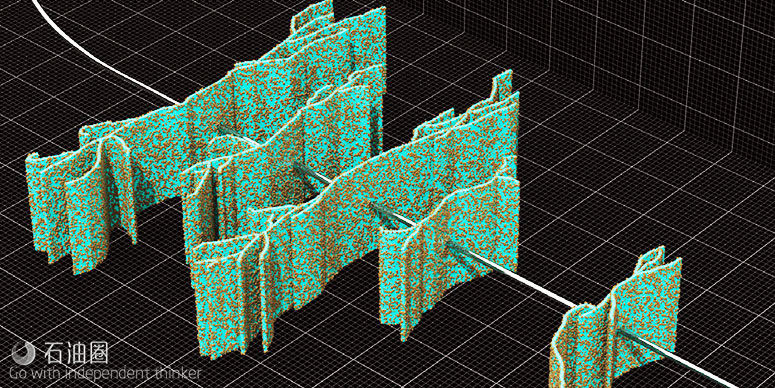

AccessFrac service uses temporary diverting agents including BioVert? agent, the industry’s first chemical diverter proved to meet the requirements of fracturing. This biodegradable material provides effective diversion by sealing perforations and then dissolving, leaving the perforations, fractures and wellbore open.

The diverting agent can be used to provide temporary isolation of newly stimulated perforation clusters within the treatment interval. The perforations receiving the early fluid and proppant volumes can be temporarily isolated, diverting further treatment to additional sets of perforations.

In multi-zone treatments, as many as two out of every three frac plugs can be replaced by chemical diversion techniques.

Near-Wellbore and In-Fracture Diversion

The AccessFrac diverting agent can be tailored to provide both diversion at the perforations and diversion inside the fracture network. Using the two in combination can be a very effective approach to improving fracturing results by stimulating more perforation clusters and by creating more fracture network complexity.

Case History1

An operator in the Haynesville used AccessFrac PD service to combine the last two or three stages on seven wells. For one well, the design included perforating the last three stages of the well all at one time, resulting in approximately 700 ft of the lateral that was stimulated with the AccessFrac PD service technique.

Over about 8 hr of continuous pumping, we placed nearly one million pounds of proppant across the entire perforated interval. Each of the four stimulation treatments resulted in positive pressure responses.

Halliburton’s on-site technical professionals provided real-time diversion and fracture analysis to aid in on-the-fly decision making. This helped to optimize each treatment performed in the series and to gather information for future completions.

Case History2

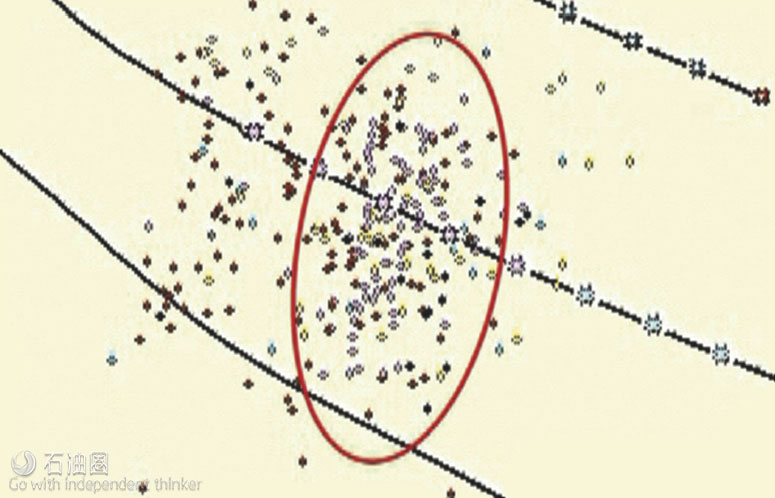

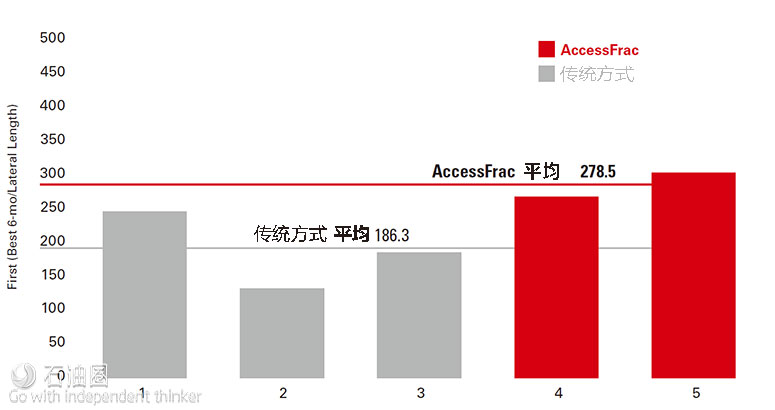

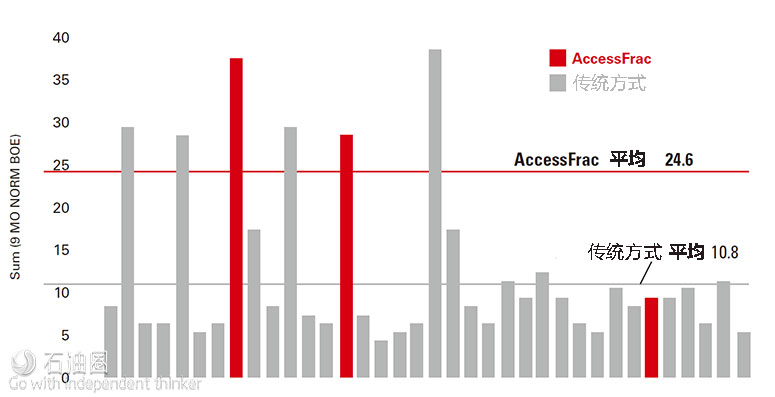

Seven operators in seven different formations have used AccessFrac CF service in more than 30 wells and 450 fracturing stages. These wells have achieved important improvements in production compared to conventional approaches.

In ultra-tight formations like shale, operators often experience rapid production declines following fracturing treatments. This can be the result of less-than-optimal reservoir contact due to uneven proppant distribution during plug-and-perf operations.

Whether you’re producing oil, gas or both, AccessFrac service addresses these challenges. We tailor each treatment to maximize production given the unique conditions found in your well.

石油圈

石油圈