Marine Sentry™ RCD 3000 Rotating Control Device

The Halliburton services Marine Sentry™ rotating control device (RCD) provides a pressure control solution by creating a dual passive seal around the rotating drill string and tool joints to divert annulus returns during conventional or managed pressure drilling operations. The Marine Sentry RCD is “fit for purpose” for offshore Jackup and Fixed Platform rigs and is mounted on the rigs surface blowout preventer (BOP) stack. The system incorporates advanced smart monitoring of key functions of the rotating control device to help reduce cost and environmental impact while improving overall well site safety in pressure-critical operations.

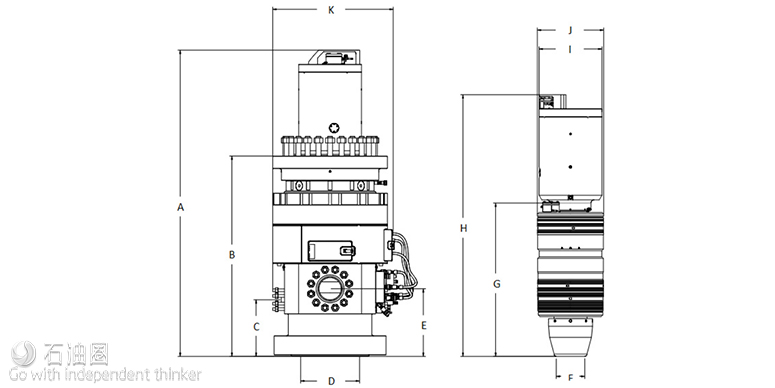

The Marine Sentry RCD is equipped with remote latching design, which assists in the safe and secure operation by the rig personnel. The system includes a hydraulic power unit (HPU) for on demand oil lubrication of bearings and seals, and dedicated cooling system.

Rated to 3,000 psi (20.7 Mpa) static pressure and 2,000 psi

(13.8 Mpa) dynamic, the Marine Sentry RCD creates a pressure tight barrier between fluid returns and personnel on the rig floor, helping to safely contain annular fluids under pressure while drillpipe is rotating, and diverting fluids below the rigfloor to the returns system without interrupting operations.

A range of available accessories includes test plug/casing stripping adapter, seal bore protector, and mechanical running and pulling tools for efficient deployment of bearing/seal element assembly and adapters through the riser tieback for latching/unlatching from the body.

Applications

The Marine Sentry RCD device helps enhance HSE through total control of surface pressure in a range of pressure-critical drilling applications:

•Managed pressure drilling (MPD), underbalanced drilling (UBD), air drilling, continuous circulating system (CCS), mud cap drilling (PMCD) and kick control in conventional drilling

•Shallow gas and abnormally pressured formations

•Casing while drilling

•Offshore Fixed Platform or Jackup rig

•Extended-reach horizontal and ultra-deep vertical wells

Features

•API 16RCD Monogram

•Certified to CE / ATEX / NORSOK and DNV 2.7-1 / 2.7-3

•Rated to 3,000 psi (20.7 Mpa) static pressure, 2,000 psi (13.8 Mpa) dynamic

•Remote latching system can enable operator to safely and

securely latch or unlatch bearing/seal element and accessory equipment without manual operation by personnel below rig floor or in the moon pool on offshore rigs

•HMI workstation equipped to display all critical information and provides safety interlock control to help prevent accidental unlatch of bearing/seal element under pressure. Latching system is designed with redundant latch and un-latch mechanisms along with mechanical override.

•Wireless monitoring for bearing rpm, vibration, pressure and temperature between elements, lubricating oil at the bearing, and well bore

•HPU unit provides cooling independent of on-demand lubrication to bearing assembly

•System easily deployable through most rotaries

•InSite® system capable for real-time operations

Benefits

Marine Sentry RCD can provide these benefits:

•Improves safety and efficiency in pressure-critical applications

•Maintains tight control of drilling fluid to enhance HSE

•Seamless integration with managed pressure drilling systems to reduce nonproductive time, reduce cost through ROPimprovement and casing program optimization

Case Study

Engineered Solution Enables Operator to Successfully Drill Reentry Well in Gulf of Mexico

CHALLENGES

» Safely and efficiently drill reentry well in Gulf of Mexico

» Maintain bottomhole pressure control within a 0.7-pound-per- gallon overall pore/fracture pressure drilling window

SOLUTIONS

» Marine Sentry™ RCD 3000 rotating control device to close drilling loop for GeoBalance® MPD system

» GB Setpoint™ advanced real- time hydraulic model to maintain bottomhole pressure just above the pore pressure while drilling and tripping

» Geo-Pilot® RSS to safely drill reentry well to total depth

RESULTS

» Safely executed drilling program without non- productive time.

» Drilled hole section with one dual element bearing run, stripped over 25,000 ft

» Provided stable wellbore for completion

For a customer in the Gulf of Mexico, Halliburton provided an integrated drilling service that included the Marine Sentry™ RCD 300 rotating control device and the GeoBalance® managed pressure drilling (MPD) service. The Marine Sentry RCD 3000 device provided the closed drilling loop for the MPD system that was implemented to mitigate drilling risks associated with a narrow 0.7-pound-per-gallon drilling window. The GeoBalance MPD system, the GB Setpoint™ advanced real-time hydraulic model, and the Geo-Pilot® rotary steerable system (RSS) were used to safely and successfully drill the reentry well to reach a total measured depth of 17,485 feet (5,329 meters).

Narrow-pressure drilling windows can cause borehole instability, along with associated shale breakouts occurring from pressure cycling of the borehole, downhole mud losses, surge and swab effects, and possible kicks.

This Gulf of Mexico field, which is 372 feet (113 meters) deep, presented a number of risks and drilling challenges due to narrow-pressure drilling windows. Borehole instability, mud loss issues, and drilling risk mitigation were main drivers for the operator to seek an MPD solution. Halliburton was asked to provide an integrated drilling solution to safely and effectively drill the intervals within a 0.7-pound-per-gallon overall pore/ fracture pressure drilling window because of the depletion of the upper reservoir.

Halliburton provided an engineered solution that utilized the Marine Sentry™ RCD 3000, Geo-Pilot® rotary steerable system;

GeoBalance® MPD equipment; the GB Setpoint advanced real-time hydraulic model, which tracks different fluid densities and rheology to calculate the proper surface pressure to maintain bottomhole pressure just above the pore pressure while drilling and tripping.

Not only was the well drilled safely without non-productive time, the entire hole section was drilled with one Marine Sentry™ RCD 3000 bearing run, maintaining pressure sealing with dual elements over 25,000 feet of stripping. The well bore was left in a stable condition to successfully cement the well for completion.

石油圈

石油圈